Signal transmission butterfly valve used in fire pipeline environment

Signal transmission butterfly valve used in fire pipeline environment

Signal butterfly valve is suitable for petroleum, chemical industry, food, medicine, papermaking, water and electricity, ships, water supply and drainage, smelting, energy and other system pipeline. It can be used as regulating and throttling equipment on a variety of corrosive and non-corrosive gas, liquid, semi-fluid and solid powder lines and containers.

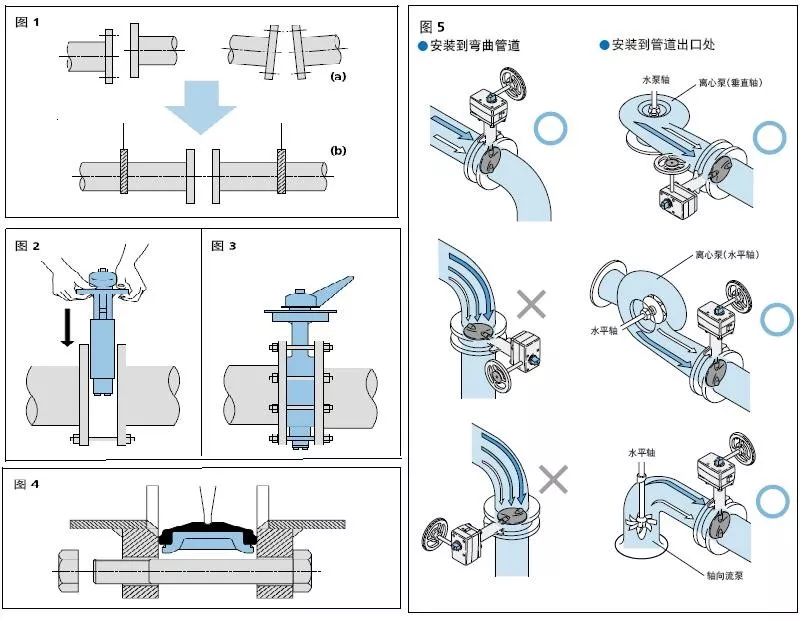

1, small and light, easy to disassemble and maintenance, and can be installed in any position.

2, simple structure, compact, 90° rotating open and close quickly.

3, the operation torque is small, labor saving and lightweight.

4, to achieve complete sealing, gas test leakage is zero.

5, choose different parts material, can be suitable for a variety of media.

6, flow characteristics tend to straight line, good regulation performance.

7, opening and closing test times up to ten thousand times, long service life.

8, where the use of gate valve, check valve (ball stop valve)”> globe valve, plug valve, hose valve and diaphragm valve pipeline, especially in high-rise building fire system and need to show the valve switch status of the pipeline system, can be replaced by the valve.

Working principle of

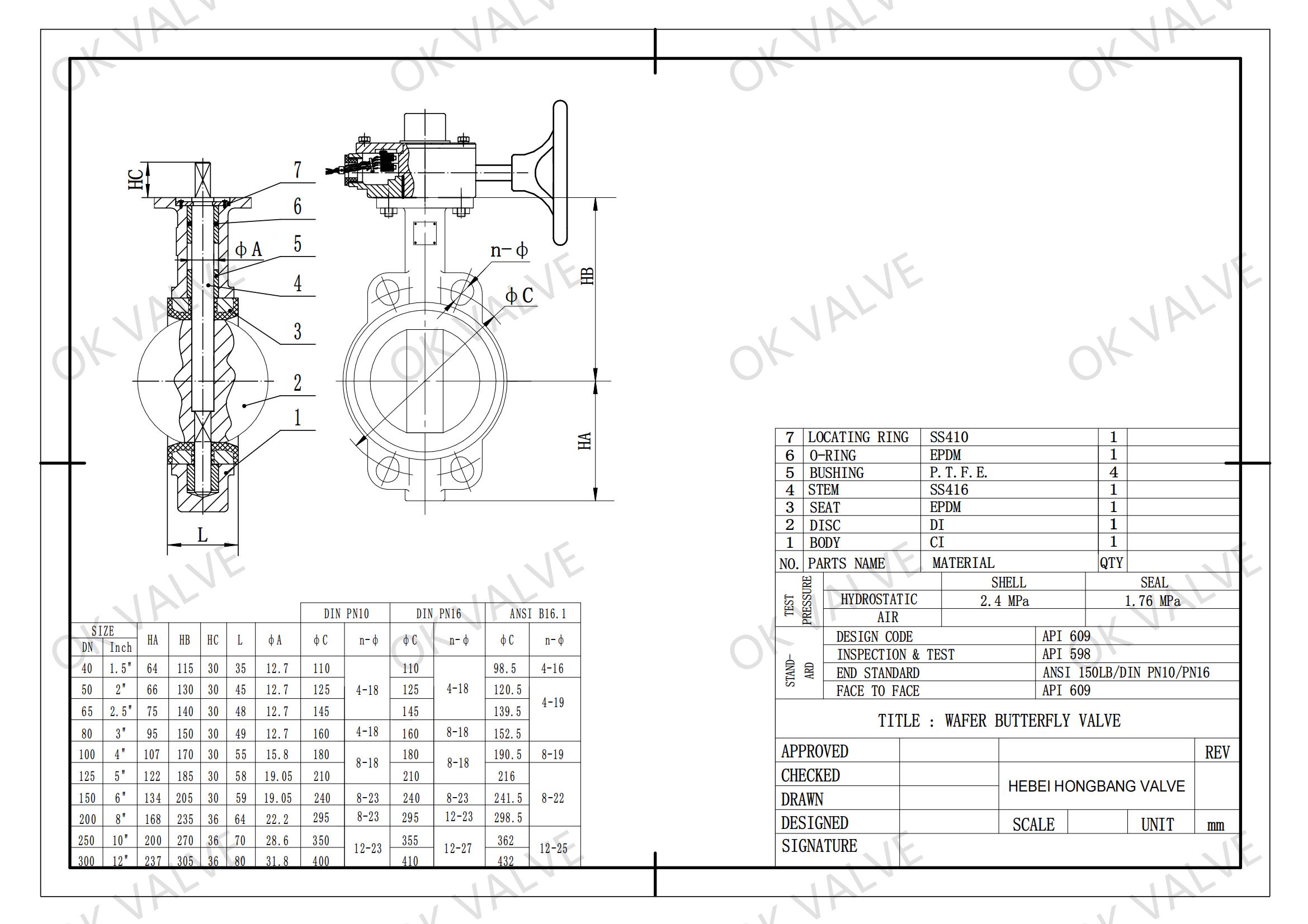

1. Signal butterfly valve is driven by worm gear and worm drive shaft and butterfly plate rotation to realize opening and closing and control flow.

2. Rotate the handwheel of worm gear and worm drive device to achieve the purpose of opening and closing the butterfly plate and adjusting the flow. The handwheel rotates clockwise to close the valve.

3, Worm gear worm drive device box set in the micro switch has two forms:

A. There are two micro switches in the transmission device box, open and close, which operate when the valve is fully open and closed respectively. The light source of “valve open” and “valve close” in the control room is connected, so as to accurately display the valve switch status.

B, in the transmission device box is equipped with a close micro switch (butterfly plate full close position is 0°), when the butterfly plate from 0°~40° position micro switch support, output valve closing signal, 40°~90° position another pair of normally closed can output valve opening signal. The CAM can be adjusted to show the different positions of the butterfly plate.

Method of use

Worm gear transmission device use adjustment and connection method

1. Open the electrical switch cover, connect the cable core wire to the corresponding terminal according to the electrical control requirements, seal the cable inlet, and fix the cable to prevent damage to the cable connection when the external force is affected.

2, When the valve in the “fully closed” position, clockwise turn the following close to the CAM, is the CAM just touch the micro switch (can hear the click), and then tighten the screw on the CAM to fix the CAM.

3. When the valve is in the “fully open” position, rotate the open CAM counterclockwise and adjust the open CAM in the same way as above.

4, Adjust the limit screw, when the valve in the “fully closed” or “fully open” position, should not make the limit screw just on the limit plane of the worm gear, but should leave a certain gap, and then tighten the lock nut on the limit screw.

5. Cover the electric switch box cover. When the valve is in the “all off” position, make the pointer of the opening indicator point to the “0″ scale on the dial, and tighten the screw to fix the pointer.